Mastering Inventory Management: Streamlining Operations for Seamless Efficiency

Home >> Insights >> Mastering Inventory Management: Streamlining Operations for Seamless Efficiency

Home >> Insights >> Mastering Inventory Management: Streamlining Operations for Seamless Efficiency

In the bustling world of business, the heartbeat of success lies in one often overlooked aspect—Inventory Management. It's not just about storing goods; it's a symphony of strategies orchestrating when to order, how much to order, and where to store. Let's dive into the intricacies and unveil the secrets that can elevate your business game.

Inventory management is the silent conductor ensuring the right products are in the right place at the right time. From raw materials to finished products, it's a delicate balance. The goal? Having a pulse on inventory visibility, fostering timely deliveries, reducing turnaround times, and preventing stockouts and markdowns.

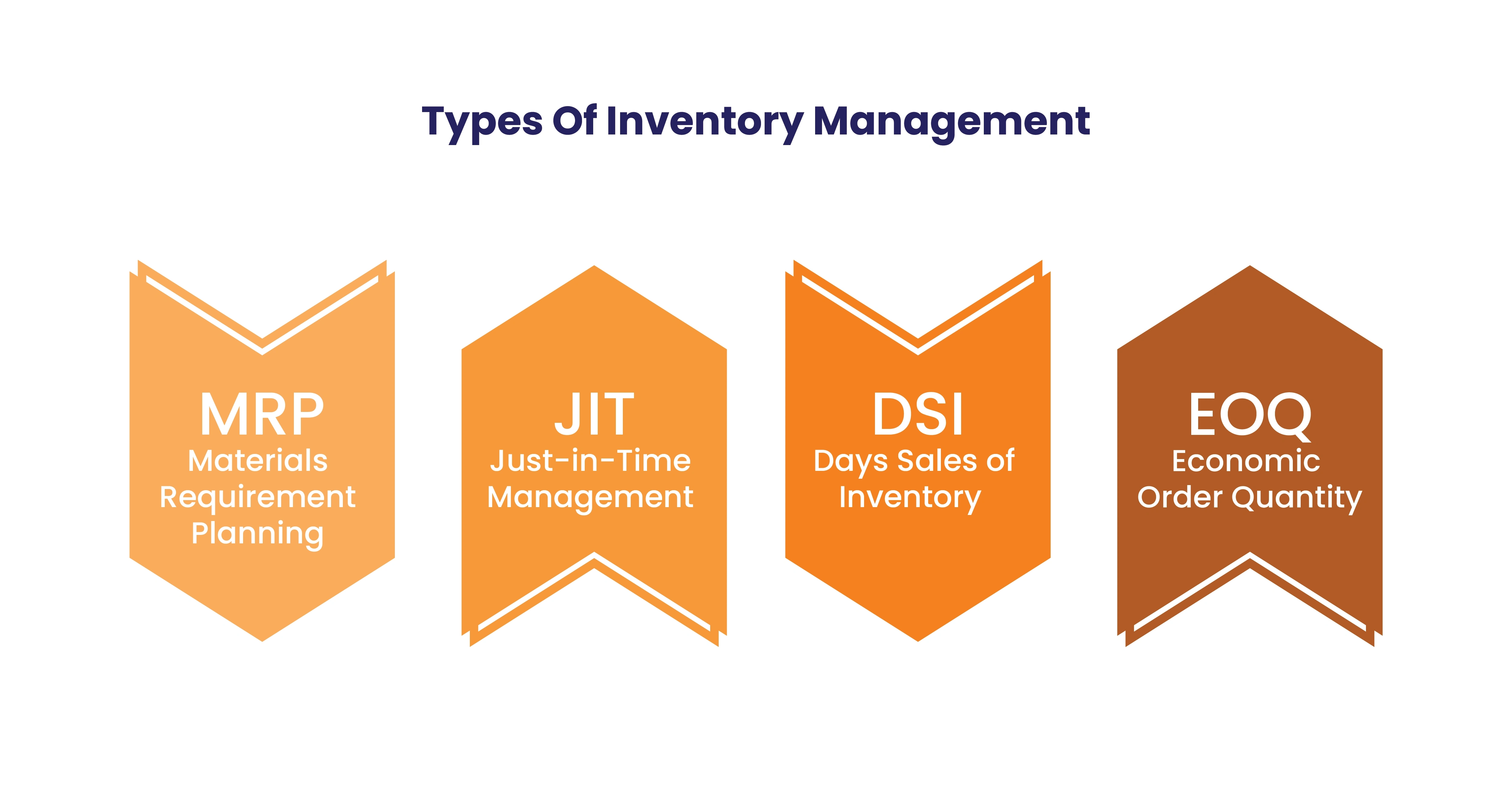

Picture this - minimizing inventory levels, reducing tied-up capital, but vulnerable to supply chain disruptions. JIT is an art that demands precise forecasting and steadfast suppliers.

A system planning and controlling production, MRP ensures materials align with production needs. Efficient, but a gambit that relies heavily on accurate demand forecasting.

The formula for optimal order quantity, EOQ minimizes total inventory costs. A strategic move, yet one that assumes a constant demand rate.

Measure the days a company takes to sell its entire inventory. A snapshot of efficiency but lacks insights into turnover reasons.

Inventory Management Statistics (Highlights)

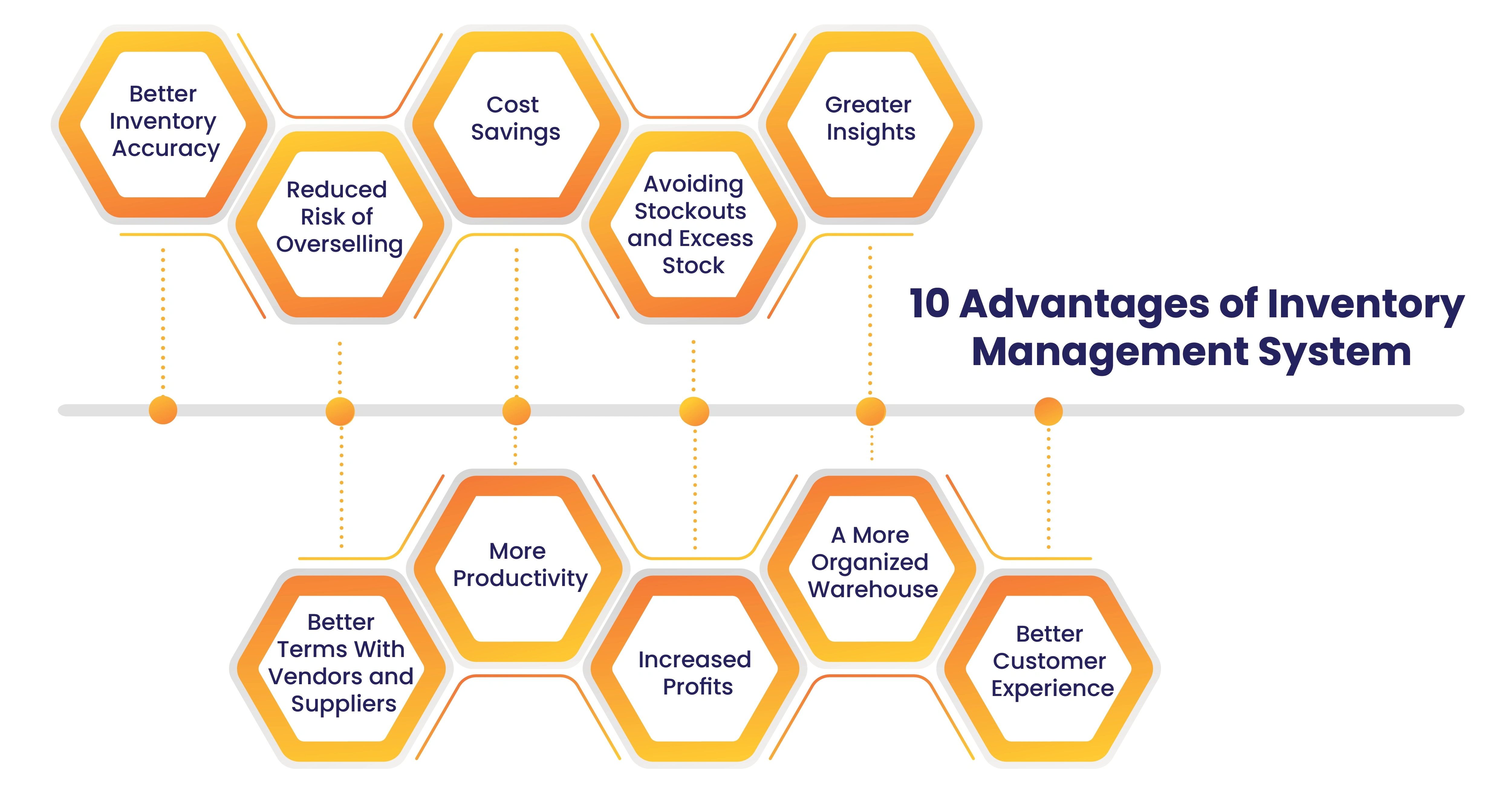

In the realm of accurate inventory management, businesses gain a precise understanding of what products are in stock at any given moment. This involves real-time tracking of inventory levels, enabling companies to maintain a comprehensive and up-to-date record of their available stock. With accurate inventory information, businesses can make informed decisions regarding restocking, ordering, and fulfillment.

Why it mattersAccurate real-time tracking prevents product unavailability, ensuring a seamless shopping experience.

Timely ReorderingEnables businesses to reorder products at the right time, avoiding delays and revenue loss.

Overselling occurs when a company sells more units of a product than are actually available in the inventory. Inventory management helps mitigate this risk by providing real-time insights into stock levels and order fulfillment.

Why it mattersAvoiding overselling is crucial for customer trust and reputation.

Operational EfficiencyAligning sales with actual inventory minimizes manual interventions and ensures efficient operations.

Effective inventory management contributes to significant cost savings for businesses. This involves optimizing the balance between maintaining sufficient stock to meet demand and avoiding excess inventory that can lead to additional costs.

Why it mattersOptimizing inventory levels minimizes storage, insurance, and handling costs.

Minimized Obsolete Inventory RiskPrevents overstocking, reducing the risk of holding inventory and losing value over time.

Better planning and management in inventory control are paramount for a business to minimize the occurrence of stockouts or excess stock. This involves strategic decision-making on when and how much to reorder, ensuring that products are consistently available to meet customer demand.

Why it mattersPrevents stockouts, enhancing customer satisfaction and loyalty.

Cost EfficiencyMinimizes excess stock, reducing holding costs and improving financial efficiency.

Inventory tracking and stock control provide businesses with valuable insights into sales trends, allowing them to make informed decisions. This involves monitoring product movement, identifying popular items, and tracking critical information such as product recalls or expiry dates.

Why it mattersInforms strategies based on sales trends and popular items.

Risk MitigationTracks recalls and expiry dates for risk management and compliance.

Effective inventory management offers insights into product demand and sales volumes, empowering businesses to negotiate better prices and terms with their vendors and suppliers.

Why it mattersAllows negotiation for better pricing and terms, reducing procurement costs.

Strategic PartnershipsStrengthens relationships with suppliers, ensuring a reliable supply chain.

Implementing good inventory management solutions saves valuable time that can be redirected towards other core activities of the business. Automation and streamlined processes contribute to increased overall productivity.

Why it mattersAutomation and streamlined processes free up time for core business activities.

Time SavingsTime saved on manual tasks can be reinvested in product development or strategic planning.

A better understanding of both product availability and demand leads to higher inventory turnover, ultimately resulting in greater profits for the business.

Why it mattersHigher turnover reduces overstocking risks and associated costs.

Revenue MaximizationAligning availability with demand boosts revenue and profit margins.

Efficient inventory management contributes to an organized warehouse by arranging items based on demand, sales frequency, and other relevant factors. This organization reduces labor costs and speeds up order fulfillment.

Why it mattersOrganized warehouses speed up order fulfillment, improving customer satisfaction.

Cost SavingsMinimizes labor costs associated with disorganization.

Customers who receive their orders on time and as expected are more likely to become loyal patrons. This positive experience is a direct result of effective inventory management ensuring product availability and timely order fulfillment.

Why it mattersTimely and reliable order fulfillment fosters loyalty and positive recommendations.

Brand ReputationEnhances overall customer experience, positively impacting brand reputation.

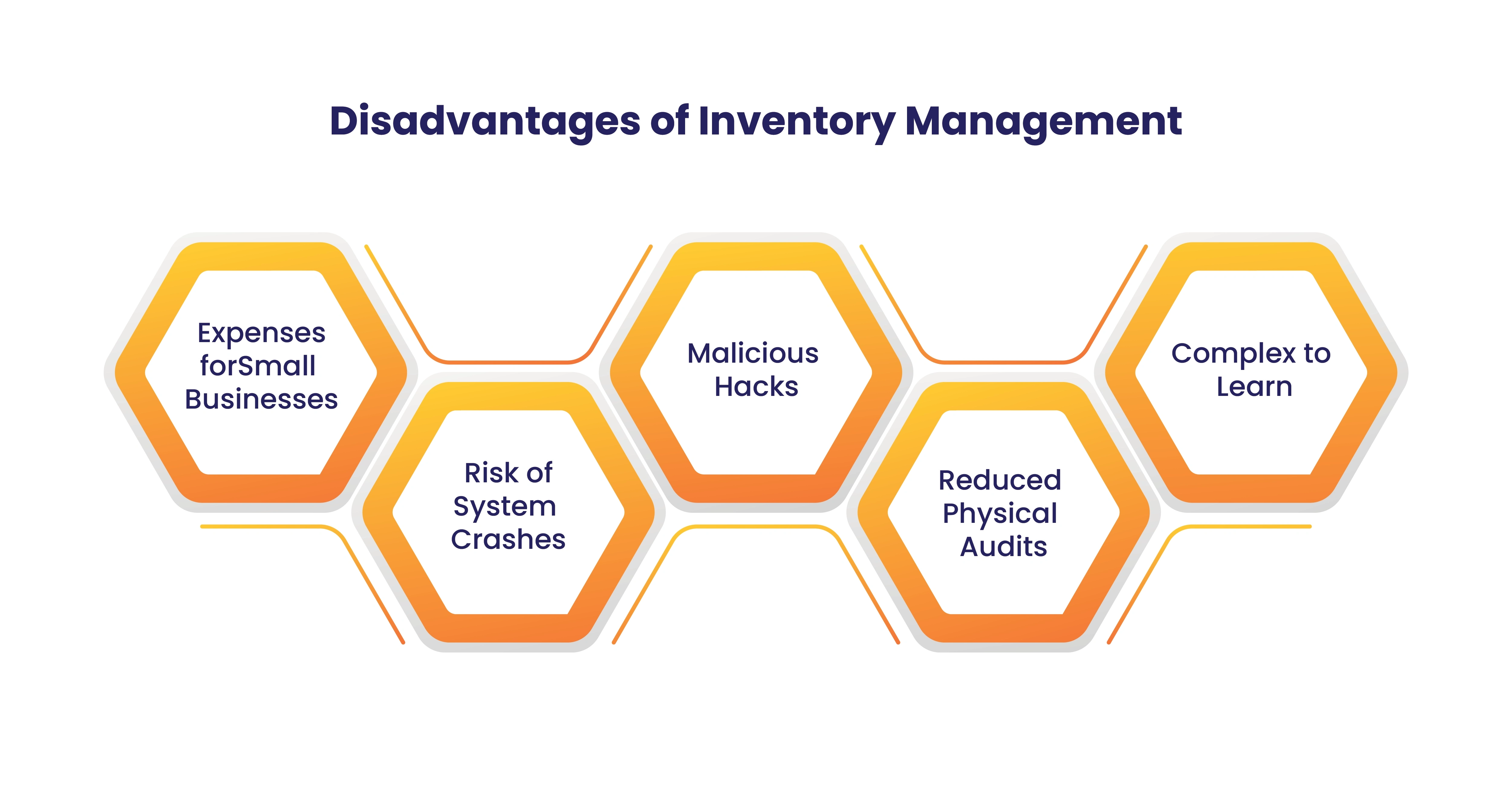

Small businesses may find implementing inventory management systems costly, covering software purchases and employee training. Initial expenses can be challenging for those on tight budgets.

Like all software, inventory management systems are vulnerable to technical issues, including system crashes. Downtimes can disrupt operations, leading to delays and potential customer dissatisfaction.

In the digital age, the security of inventory management software is crucial. Malicious hacks pose a serious threat, risking unauthorized access, data theft, and supply chain disruptions.

Automated warehouse operations may decrease physical audits, potentially overlooking discrepancies. Regular physical audits are essential to align digital records with actual stock, minimizing discrepancies.

Inventory management software complexity can be challenging for new users. Investing in online training helps employees quickly grasp the software's functionalities, ensuring smoother transitions and optimal system use.

Key Features of Effective Inventory Management

Ensure real-time visibility with advanced systems like barcoding or RFID. Accurate tracking reduces errors, minimizes stockouts, and optimizes stock levels.

Streamline the order process with automated functionalities. From order processing to tracking, create a seamless workflow for prompt order fulfillment.

Generate insightful reports for data-driven decisions. Metrics like inventory turnover and fulfillment times provide valuable insights into overall performance.

Optimize inventory levels using historical data and predictive analytics. Identify patterns, understand seasonality, and make informed decisions for efficient inventory management.

Create an efficient procurement process with automated replenishment and supplier relationship management. Streamline purchasing to minimize costs and reduce lead times.

Managing inventory comes with its fair share of challenges. Here are some common issues that businesses face

Running out of stock can lead to missed sales opportunities and frustrated customers. It's crucial to have a system in place to monitor stock levels and reorder products in a timely manner.

On the other hand, having excess inventory ties up valuable capital and can result in increased carrying costs. It's important to strike the right balance and avoid overstocking.

Accurate demand forecasting is essential for effective inventory management. If you don't have a clear understanding of customer demand, you may end up with too much or too little inventory.

If you can't see your inventory levels in real-time or track items throughout the supply chain, it becomes difficult to make informed decisions. Having visibility into your inventory is crucial for effective management.

Relying on manual processes, such as spreadsheets or pen-and-paper tracking, can be time-consuming and prone to errors. Adopting automated inventory management solutions can help streamline operations and reduce human error. Now that we've identified some of the common challenges, let's explore the techniques and best practices to overcome them.

the best practices that will transform you into an inventory virtuoso.

No more crystal ball reliance. Accurate forecasting is your ticket to predicting customer demand with surgical precision. Avoid the pitfalls of surplus stock or frustrating stockouts by harnessing the power of data – analyze historical trends, customer behavior, and market dynamics to stay ahead of the demand curve.

Consider reordering points to your strategic allies. Optimize them, and you'll bid farewell to excess inventory woes and stockout nightmares. Dive into the realms of historical data, customer trends, and market fluctuations to pinpoint the reorder points that maintain your inventory equilibrium. No more panic-induced purchases or clinging onto dead stock – just smooth sailing.

Yes, audits might sound like a snooze-fest, but they're your inventory's guardian angels. Regular audits ensure accurate stock counts, minimize discrepancies and unveil any potential theft or loss. It's your ticket to an organized warehouse where items don't vanish mysteriously. Grab that clipboard and channel your inner inventory detective.

In the intricate dance of inventory management, communication reigns supreme. It's not about sweet-talking your inventory (although that would be amusing!). Effective communication means establishing clear lines between departments, suppliers, and customers. Consider it your inventory telegraph system – keeping the messages flowing for seamless operations.

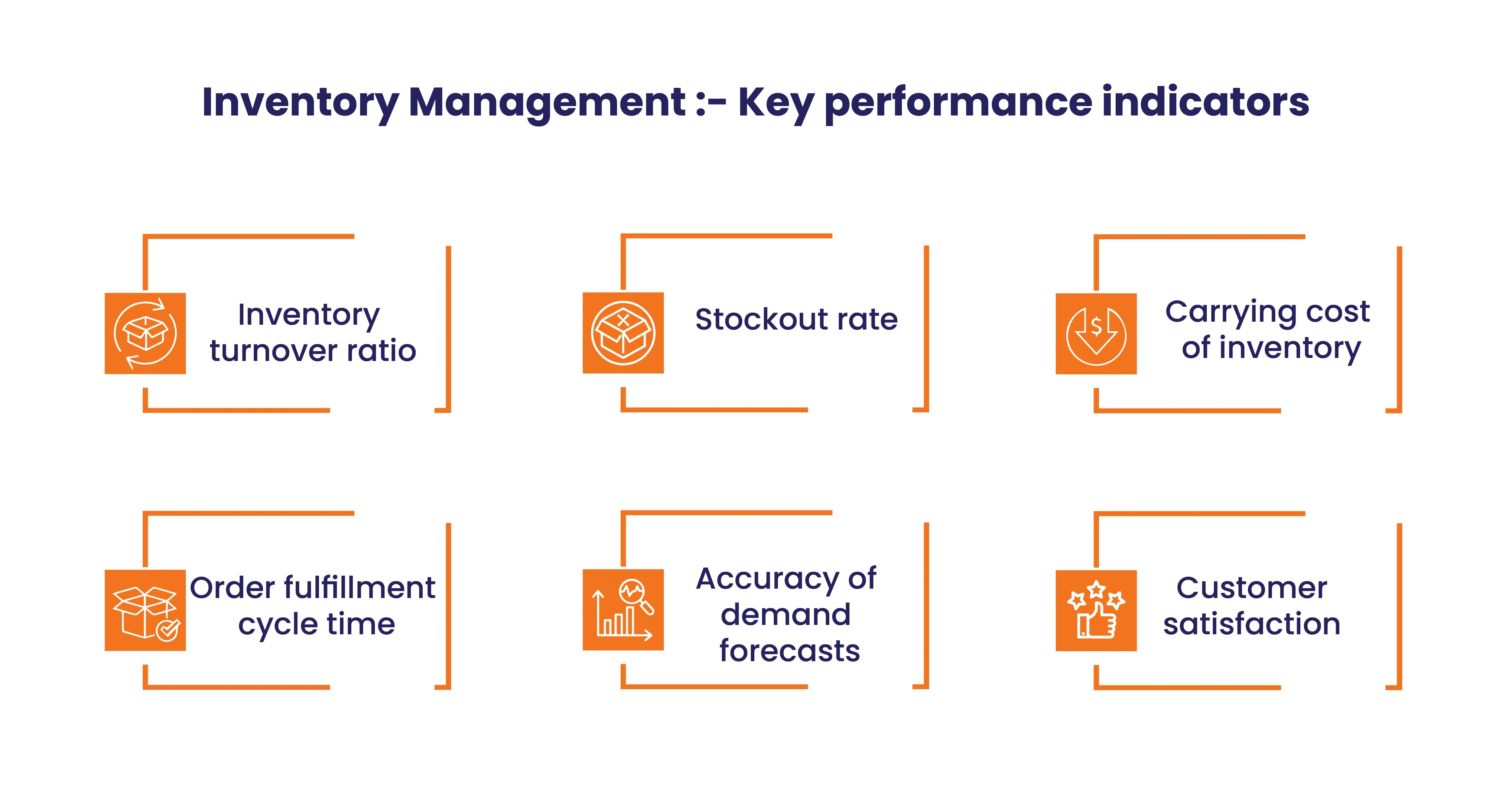

Measuring and monitoring key performance indicators (KPIs) is crucial for evaluating your inventory management performance. Here are some common KPIs to consider:

This metric measures how quickly you sell your inventory. A high inventory turnover ratio indicates efficient inventory management, while a low ratio may suggest overstocking or slow-moving products.

The stockout rate measures the percentage of time that you experience stockouts. A low stockout rate indicates effective inventory management, while a high rate may suggest poor forecasting or inadequate inventory control.

The carrying cost of inventory includes costs such as storage, insurance, and handling. Monitoring this metric helps you identify opportunities to reduce costs and improve efficiency.

This metric measures the time it takes to process and fulfill customer orders. A shorter cycle time indicates efficient order fulfillment and customer satisfaction.

Measuring the accuracy of your demand forecasts helps you identify areas for improvement and ensure that you have the right inventory levels to meet customer demand.

While not directly related to inventory management, customer satisfaction is a crucial KPI to monitor. Satisfied customers are more likely to become repeat buyers and recommend your business to others.

Regularly monitoring these KPIs and making necessary adjustments can help you continually improve your inventory management and achieve better results.

Effective inventory tracking and control

Accurate inventory tracking and control are essential for efficient inventory management. Here are some best practices to ensure effective tracking and control

Utilize barcode or RFID technology to track inventory items. This allows for quick and accurate scanning, reducing the chances of errors in tracking.

Instead of relying solely on physical inventory counts, implement regular cycle counting. This involves counting a portion of your inventory on a regular basis to ensure accuracy.

Assign specific locations for each item in your inventory. This makes it easier to locate items and reduces the time spent searching for products.

Implement the FIFO method for managing perishable or time-sensitive items. This ensures that older items are sold or used first, reducing the risk of spoilage or obsolescence.

Maintain safety stock levels to account for unexpected increases in demand or delays in the supply chain. This helps prevent stockouts and ensures that you can meet customer demand even in challenging circumstances.

Regularly reconcile your physical inventory counts with the recorded quantities in your system. This helps identify any discrepancies and ensures that your inventory records are accurate.

By implementing these inventory tracking and control practices, you can minimize errors, improve efficiency, and have greater control over your inventory.

Why is Inventory Management Important?

Inventory isn't just a line item on a balance sheet; it serves as the central hub where all elements of the supply chain intersect. It's the heartbeat of a company's operations, influencing customer satisfaction, operational efficiency, and ultimately, the bottom line.

Imagine a scenario where there's too little inventory when and where it's needed. This scarcity can lead to unhappy customers, missed opportunities, and a tarnished reputation. On the flip side, a surplus of inventory poses its own set of challenges—increased storage costs, the risk of spoilage, theft, and potential shifts in demand that could render stock obsolete.

Inventory management isn't just about having enough products in the warehouse; it's about having the right products, in the right quantities, at the right time. This strategic orchestration is what keeps the supply chain humming and the business thriving. In the intricate dance of commerce, inventory management takes center stage, directing the rhythm of production, distribution, and customer satisfaction.

In the Future, These Technologies Will Continue to Transform Inventory Management

Intelligent, self-correcting AI for accurate monitoring and reduced material waste.

Data from IoT sensors provide insights into inventory location and status.

A unified and immutable record connecting disparate parties through all transactions.

Mastering inventory visibility with improved demand forecasting and automation.

Unprecedented computational power solving previously unsolvable problems.

As we navigate inventory management, remember—the goal is efficiency. Embrace the evolving technologies, leverage real-time insights, and let your inventory be not just a silent asset, but a strategic powerhouse. Maximize efficiency, minimize risks, and orchestrate a seamless symphony in the heart of your business.

We discussed the different types of inventory, The Importance of Inventory Management, Inventory Management Techniques like Just-in-Time (JIT), ABC Analysis, and Economic Order Quantity (EOQ).

Choosing the right inventory management system is crucial for any business, and we delved into the key features to look for and the customization options available. We then explored the advantages & benefits of inventory management, including cost savings, improved cash flow, and customer satisfaction.

And there you have it, folks! We've successfully navigated the waters of inventory management, uncovering its importance, techniques, and benefits along the way. Now armed with this knowledge, I'm sure you're ready to tackle any inventory management situation that comes your way.

Remember, inventory management is the key to maintaining a well-oiled machine when it comes to your business operations.